Beyond a Simple Fix – The Science of Hybrid Battery Reconditioning

When your Toyota Prius (or other hybrid like a Lexus, Nissan, Kia, or Hyundai) starts showing signs of a weakening battery in the Las Vegas heat, the thought of expensive replacements can be daunting. But what if there was a way to restore your existing battery to near-new performance, at a fraction of the cost, and with a robust warranty? This is precisely what professional hybrid battery reconditioning offers.

However, not all reconditioning processes are created equal. Many misconceptions arise from simple “module swaps” or superficial fixes that offer only temporary relief. At Prius Battery Repair LV, we employ a proprietary, advanced reconditioning process that goes far beyond just replacing a few weak cells. Our method is a meticulous, multi-step procedure designed to restore the entire battery pack to optimal health, ensuring longevity and reliable performance for years to come.

As your trusted hybrid battery specialists in Las Vegas, we believe in transparency. Understanding our process will not only give you peace of mind but also highlight why our reconditioned batteries stand out in terms of quality, performance, and the unparalleled 4-year unlimited miles warranty we offer on specific Prius generations. Let’s pull back the curtain on how we bring hybrid batteries back to life.

1. The Initial Assessment: Precision Diagnostics are Key

Before any reconditioning begins, the first crucial step is a comprehensive diagnostic evaluation of your hybrid battery pack. This isn’t just about reading basic error codes; it’s about understanding the internal health of the entire system.

- Vehicle Scan & Code Analysis: We start by connecting to your vehicle’s onboard diagnostic system to retrieve all relevant fault codes and data from the Battery Management System (BMS). This provides initial clues about which parts of the battery might be underperforming.

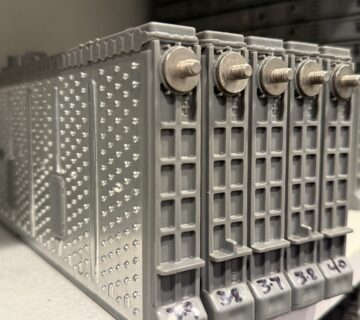

- Module-Level Testing: The real magic begins here. A hybrid battery pack is composed of many individual modules (e.g., a Prius battery typically has 28 modules). We don’t just test the overall pack; we test each individual module for voltage, internal resistance, and capacity. This is critical because a battery is only as strong as its weakest link. Identifying precisely which modules are weak, failing, or inconsistent is the foundation of a successful reconditioning.

- Thermal Inspection: We also assess the battery’s cooling system and look for signs of overheating or uneven temperature distribution, as heat is a major enemy of hybrid battery longevity, especially in Las Vegas.

This rigorous initial assessment ensures we have a complete picture of your battery’s “state of health” and allows us to tailor our reconditioning approach precisely to its needs.

2. Disassembly & Module Extraction: The Surgical Phase

Once the diagnostics are complete, the battery pack is carefully removed from your vehicle and brought to our specialized workshop. Safety is paramount during this stage due to the high voltage involved.

- Controlled Environment: All work is performed in a controlled, safe environment by trained technicians who understand high-voltage systems.

- Careful Disassembly: The battery pack’s outer casing is meticulously opened, and each individual module is safely disconnected and removed. This stage requires precision to avoid damaging delicate interconnections and sensors.

- Cleaning & Inspection: Bus bars (the metal connectors between modules), wiring harnesses, and the battery cooling fan assembly are thoroughly inspected for corrosion, damage, or blockages. These components are cleaned or replaced as needed to ensure optimal electrical flow and thermal management.

This meticulous disassembly prepares the individual modules for the reconditioning process.

3. The Core of Reconditioning: Deep Cycling & Cell Balancing (Our Proprietary Edge)

This is where the true “reconditioning” happens and where our proprietary process provides a significant advantage over lesser repair methods.

- Individual Module Deep Cycling: Each individual module (or small groups of modules) undergoes multiple cycles of controlled deep discharge and precise recharging. This process is crucial for:

- Breaking Down “Memory Effect”: For NiMH batteries (like those in most Priuses), repeated shallow discharge cycles can lead to a “memory effect” where the battery ‘remembers’ a lower capacity. Deep cycling helps to break down these voltage depressions and restore lost usable capacity.

- Breaking Down Sulfation: Over time, lead-acid batteries can form sulfate crystals on their plates, hindering performance. While NiMH batteries don’t experience sulfation in the same way, the cycling process helps break down similar performance-reducing formations and equalize internal chemistry.

- Precision Cell Balancing: This is arguably the most critical step for long-term battery health and what truly separates a quality reconditioning from a short-term fix. Even in a seemingly healthy module, individual cells within it can become imbalanced in terms of voltage and capacity over time due to manufacturing variances, temperature differences, and uneven aging.

- Why it’s Crucial: If left unbalanced, the weakest cells will limit the performance of the entire module (and thus the entire pack). They will be overstressed during discharge and potentially overcharged during charging, leading to premature failure of that module and cascading issues across the pack.

- Our Method: Our proprietary process utilizes advanced, computer-controlled equipment that monitors and balances each individual cell within the modules. This ensures that all cells are brought to a uniform state of charge and capacity, maximizing their collective performance and significantly extending the lifespan of the reconditioned pack. We don’t just balance the modules; we balance within the modules, ensuring true internal harmony.

- Module Matching & Grouping: After deep cycling and balancing, each module’s actual capacity is precisely measured. Modules are then carefully grouped with others of similar power and capacity. This “precision cell matching” ensures that when the pack is reassembled, there are no significant discrepancies between modules, preventing future imbalances and maximizing the overall performance and efficiency of the reconditioned battery.

This intensive, multi-cycle, and highly precise reconditioning and balancing process is what allows us to confidently offer our industry-leading warranty.

4. Reassembly & Quality Control: Building a Better Battery

With the individual modules reconditioned, balanced, and perfectly matched, the pack is ready for reassembly and final rigorous testing.

- New/Reconditioned Components: Any severely degraded or unrecoverable modules identified in the initial assessment are replaced with thoroughly reconditioned and perfectly matched modules from our inventory.

- Upgraded Bus Bars (Often Nickel Plated): We often upgrade the critical electrical connections between modules (bus bars) with high-quality, nickel-plated replacements. This is vital as original bus bars can corrode, increasing resistance and hindering performance, especially in humid or dusty environments like parts of Nevada. Nickel plating significantly improves conductivity and corrosion resistance, contributing to a longer-lasting battery.

- Thorough Reassembly: The reconditioned and matched modules, along with new or thoroughly cleaned components (like voltage sensors and temperature sensors), are carefully reassembled into the battery casing. All connections are torqued to manufacturer specifications.

- Final Pack Testing: Once reassembled, the entire battery pack undergoes a comprehensive final test. This includes load testing, capacity testing, and a final balance check to ensure the entire unit performs as expected under simulated real-world conditions. This rigorous quality control step guarantees the battery meets our high standards before it’s reinstalled in your vehicle.

5. Installation & Post-Service Check: Back on the Las Vegas Roads

The reconditioned battery is now ready to be reunited with your Prius.

- Professional Installation: Our experienced technicians safely reinstall the battery pack into your vehicle, ensuring all connections are secure and the cooling system is properly integrated. We offer free installation with our services.

- System Integration & Final Scan: After installation, we perform a final diagnostic scan to clear any codes, confirm proper communication between the battery and the vehicle’s computer, and verify that all systems are operating optimally.

- Road Test (Optional): In some cases, a brief road test may be performed to confirm real-world performance, including seamless transitions between electric and gasoline power, and improved acceleration.

The Prius Battery Repair LV Difference: Why Our Proprietary Process Matters to You

Our advanced, proprietary reconditioning process isn’t just about technical jargon; it translates directly into tangible benefits for you, the Prius owner in Las Vegas:

- Unmatched Longevity: By meticulously reconditioning, balancing, and matching all cells and modules, we create a battery pack that performs reliably for years, often extending its life beyond typical expectations for reconditioned units.

- Superior Performance: You’ll notice improved fuel economy, stronger acceleration, and more consistent hybrid system operation, restoring your Prius to its efficient best.

- Unbeatable 4-Year Unlimited Miles Warranty: Our confidence in our process allows us to offer an industry-leading warranty on specific Prius generations. This means peace of mind for years to come, knowing your investment is protected.

- Significant Cost Savings: You receive a premium, high-performance battery solution at a fraction of the cost of a new OEM battery.

- Environmental Responsibility: You’re making a greener choice by extending the life of existing components and reducing waste.

- Local Expertise: As specialists in Las Vegas, we understand the specific demands our climate places on hybrid batteries and tailor our services accordingly.

Don’t settle for a temporary fix or an uncertain outcome. When your hybrid battery needs attention, trust the experts who combine cutting-edge technology with meticulous craftsmanship.

Ready to experience the difference of a truly reconditioned hybrid battery?

Contact Prius Battery Repair LV today to learn more about our proprietary process and get a free quote for your hybrid battery service in Las Vegas! Get back to optimal efficiency and enjoy worry-free driving.

No comment